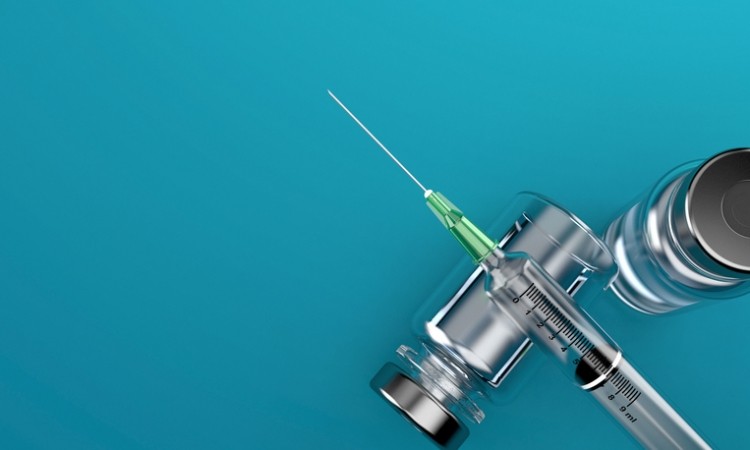

The Essential 6-Step Clinical Manufacturing Checklist for Injectable Drug Products

The manufacturing of injectable drug products for clinical trials requires meticulous attention to detail and adherence to stringent quality standards to ensure the safety, efficacy, and regulatory compliance of the final product. From formulation development to packaging and labeling, each step in the manufacturing process plays a critical role in the successful production of injectable drugs for use in clinical studies. In this article, we present a comprehensive 6-step checklist to guide pharmaceutical manufacturers through the clinical manufacturing process for injectable drug products.

Step 1: Formulation Development and Optimization

The first step in the manufacturing process is formulation development, where the active pharmaceutical ingredient (API) is combined with excipients to create a stable and effective drug product. During this stage, factors such as solubility, pH, viscosity, and compatibility with packaging materials must be carefully considered. Formulation optimization involves conducting pre-formulation studies and compatibility testing to identify the optimal formulation that meets the desired criteria for efficacy, stability, and manufacturability.

Step 2: Process Development and Scale-Up

Once the formulation is finalized, the manufacturing process must be developed and scaled up to produce clinical trial batches. Process development involves defining the critical process parameters (CPPs) and establishing the manufacturing process controls to ensure consistent product quality. Scale-up activities involve transferring the process from the laboratory to larger-scale production equipment while maintaining product quality and regulatory compliance.

Step 3: Analytical Method Development and Validation

Analytical method development is essential for ensuring the quality, purity, and potency of the injectable drug product. Analytical methods must be developed and validated to accurately measure key attributes such as API concentration, impurities, particle size distribution, and sterility. Method validation involves demonstrating that the analytical methods are accurate, precise, specific, and robust, in accordance with regulatory guidelines.

Step 4: Manufacturing and Quality Control

The manufacturing of injectable drug products must be conducted under controlled conditions to ensure product quality, safety, and consistency. Critical manufacturing steps include compounding, filling, lyophilization (if applicable), and packaging. Quality control measures, such as in-process testing, environmental monitoring, and microbiological testing, are implemented throughout the manufacturing process to verify product quality and compliance with specifications.

Step 5: Stability Studies and Shelf-Life Determination

Stability studies are conducted to assess the long-term stability of the injectable drug product under various storage conditions. These studies involve testing the drug product at defined time points to monitor changes in physical, chemical, and microbiological properties over time. The data obtained from stability studies are used to establish the product’s shelf-life or expiration date and storage conditions, ensuring that the drug product remains safe and effective throughout its intended use.

Step 6: Packaging and Labeling

The final step in the manufacturing process is packaging and labeling the injectable drug product for distribution and use in clinical trials. Packaging materials must be selected based on compatibility with the drug product and protection against light, moisture, and physical damage. Labeling requirements include providing essential information such as product name, strength, dosage form, route of administration, expiration date, storage conditions, and cautionary statements.

The manufacturing of injectable drug products for clinical trials requires careful planning, execution, and oversight to ensure product quality, safety, and regulatory compliance. By following the essential 6-step checklist outlined in this article, pharmaceutical manufacturers can navigate the complexities of the clinical manufacturing process and produce high-quality injectable drug products for use in clinical studies. Through collaboration, continuous improvement, and adherence to best practices, manufacturers can contribute to the advancement of medical science and the development of novel therapies for patients in need.